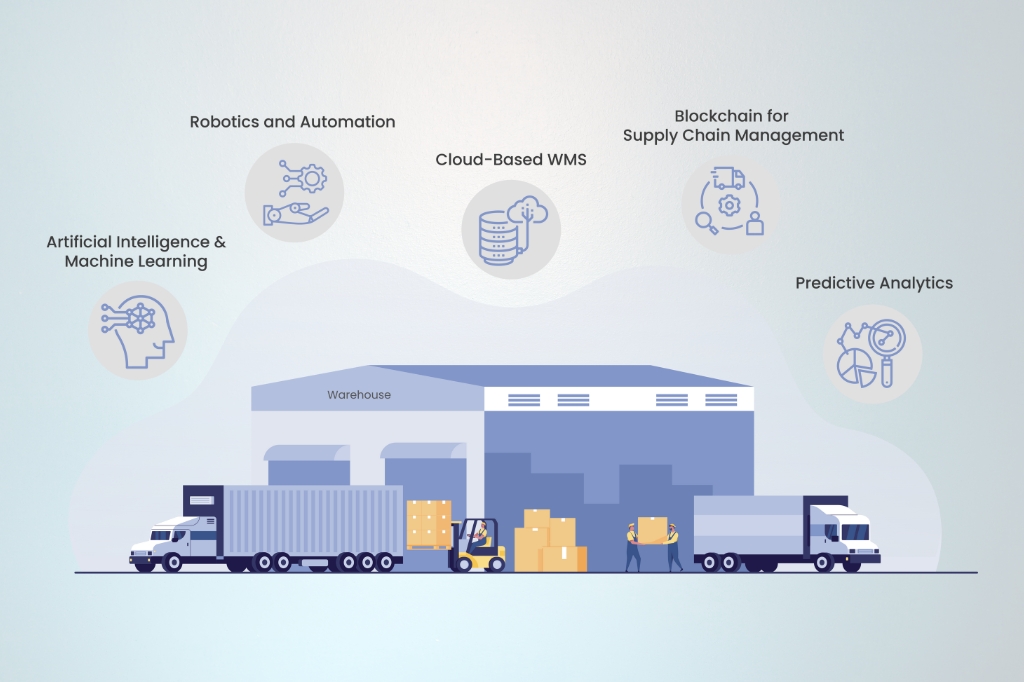

The warehouse industry is constantly evolving to meet the changing needs of businesses. One of the key drivers of change in the industry is the adoption of new technology, including warehouse management systems (WMS). In 2023, we can expect several new WMS trends that will help businesses optimize their warehouse operations and stay competitive.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) will play an increasingly important role in WMS in 2023. AI and ML can analyze vast amounts of data, from sales trends to weather patterns, and use this information to make predictions about demand for products. This allows businesses to adjust their inventory levels, optimize their staffing levels and make other strategic decisions based on real-time demand.

One of the key benefits of AI and ML in WMS is their ability to help reduce human error. By automating repetitive tasks, such as inventory management and order tracking, businesses can reduce the risk of mistakes and increase efficiency. These technologies can also identify patterns and anomalies in data that may be difficult for human workers to detect, allowing businesses to take action before issues arise.

In addition to reducing errors and increasing efficiency, AI and ML in WMS can also help businesses improve their customer service. By predicting demand for products and adjusting inventory levels accordingly, businesses can ensure that they always have the products their customers want. This could result in enhanced customer satisfaction and higher sales.

Robotics and Automation

Automation is another trend that is transforming the warehouse industry. In 2023, we can expect to see more warehouses adopt robotic systems, such as automated storage and retrieval systems (ASRS), autonomous mobile robots (AMRs), and robotic pickers. These systems can help businesses optimize their warehouse operations, reducing labor costs, and improving efficiency.

In addition to improving accuracy, robotics and automation can also help businesses reduce costs by optimizing their workflows. For example, automated guided vehicles (AGVs) can transport materials and products around the warehouse, reducing the need for human workers to do so. This can help businesses improve efficiency and reduce costs.

Another benefit of robotics and automation in WMS is their ability to help businesses scale their operations. By automating repetitive tasks, businesses can increase their capacity without needing to hire additional workers. This can help businesses grow without incurring significant additional costs.

Despite the many benefits of robotics and automation in WMS, some may be concerned about the impact on human workers. However, it’s important to note that these technologies are designed to work alongside human workers, not replace them. By automating repetitive tasks, businesses can free up human workers to focus on higher-level tasks that require critical thinking and problem-solving skills.

Overall, robotics and automation are transforming the warehouse industry, helping businesses improve efficiency, reduce costs, and increase profitability. As these technologies continue to evolve, it’s likely that we will see even more advanced robotics and automation systems in the

Cloud-Based WMS

Cloud-based warehouse management systems (WMS) are poised to become even more prevalent in 2023. These systems offer businesses a number of benefits over traditional, on-premises warehouse management system, including increased flexibility, scalability, and accessibility.

Cloud-based WMS also offer increased scalability. With on-premises systems, businesses are limited by the size of their hardware and software infrastructure. With cloud-based systems, however, businesses can easily add new users, locations, or features without needing to invest in new infrastructure.

In addition to these benefits, cloud-based warehouse management system are also typically more cost-effective than traditional, on-premises systems. With cloud-based systems, businesses pay only for the resources they use, rather than needing to make significant investments in hardware and software.

Despite these many benefits, some businesses may be hesitant to adopt cloud-based WMS due to concerns about security and data privacy. However, with the increasing adoption of cloud-based systems, security and privacy measures are becoming more robust, making it possible for businesses to leverage the benefits of cloud-based warehouse management system without compromising on security.

Overall, it’s clear that cloud-based warehouse management system are set to become even more prevalent in 2023. With their flexibility, scalability, accessibility, and cost-effectiveness, these systems offer a number of benefits over traditional, on-premises warehouse management system, and are poised to transform the way businesses operate.

Blockchain for Supply Chain Management

Blockchain is another trend that is gaining popularity in the warehouse industry. In 2023, we can expect to see more businesses adopt blockchain for supply chain management. Blockchain can help businesses track products throughout the supply chain, providing greater visibility and traceability.

One of the key benefits of blockchain for supply chain management is increased transparency. With a blockchain-based system, all parties involved in a transaction can see the same information in real-time, reducing the risk of errors, delays, and disputes.

Another benefit of blockchain for supply chain management is the ability to reduce fraud. With a tamper-proof ledger, businesses can be confident that their transactions are secure and cannot be altered or manipulated. This can help reduce the risk of fraud and increase trust between parties.

In addition to these benefits, blockchain can also help businesses improve their inventory management and supply chain planning. By providing real-time data on inventory levels, demand, and supply, businesses can optimize their inventory levels, reduce waste, and improve their overall supply chain efficiency.

Blockchain for Supply Chain Management

Predictive analytics is another trend that will become more prevalent in WMS in 2023. Predictive analytics can help businesses predict future demand for products, identify patterns in customer behavior, and optimize inventory levels. This data can be used to make better decisions about warehouse operations, such as staffing levels and product placement.

One of the key benefits of predictive analytics in warehouse management system is the ability to forecast demand and optimize inventory levels. By analyzing historical data and trends, predictive analytics can help businesses anticipate changes in demand and adjust their inventory levels accordingly. This can help reduce waste, improve customer satisfaction, and increase profitability.

Another benefit of predictive analytics in warehouse management system is the ability to identify and mitigate supply chain disruptions before they occur. By analyzing data from a variety of sources, including weather, traffic, and production schedules, predictive analytics can help businesses identify potential disruptions and take proactive measures to mitigate their impact.

In addition to these benefits, predictive analytics can also help businesses improve their overall operational efficiency. By analyzing data on the performance of various warehouse processes, such as picking and packing, predictive analytics can help businesses identify areas where they can improve efficiency, reduce costs, and optimize their workflows.

Despite the many benefits of predictive analytics in warehouse management system, some businesses may be hesitant to adopt this technology due to concerns about cost and complexity. However, as predictive analytics technology continues to evolve and become more accessible, it’s likely that we will see more businesses adopt this technology to improve their supply chain efficiency and overall profitability.

Conclusion

As we move into 2023, we can expect to see several new trends in warehouse management system that will help businesses optimize their warehouse operations and stay competitive. These trends include artificial intelligence and machine learning , robotics and automation, cloud-based WMS, blockchain for supply chain management, and predictive analytics. By adopting these new technologies, businesses can stay ahead of the curve and optimize their warehouse operations for greater efficiency and profitability.

Recent Blogs

How Manufacturing Inventory Management Software Enhances Supply Chain Efficiency

Driving Operational Excellence in In-Plant Logistics with SKUBIQ